2024

0

2023

SIMONSWERK GROUP at BAU

2020

2019

The Colcom Group strengthens the Group

2017

SIMONSWERK is a majority shareholder in Anselmi & C. S.r.l.

2009

VARIANT Planum - reduced to the essentials

2002

The concealed TECTUS hinge system comes onto the market

2000

1997

The SIKU 3D hinge system for PVCu entrance doors come onto the market

1997

SIMONSWERK POLSKA and SIMONSWERK UK Ltd. sales companies founded

1992

The production facility in Heiligenstadt opens

1990

The VARIANT VX knuckle hinge system for heavy-duty doors is developed

1986

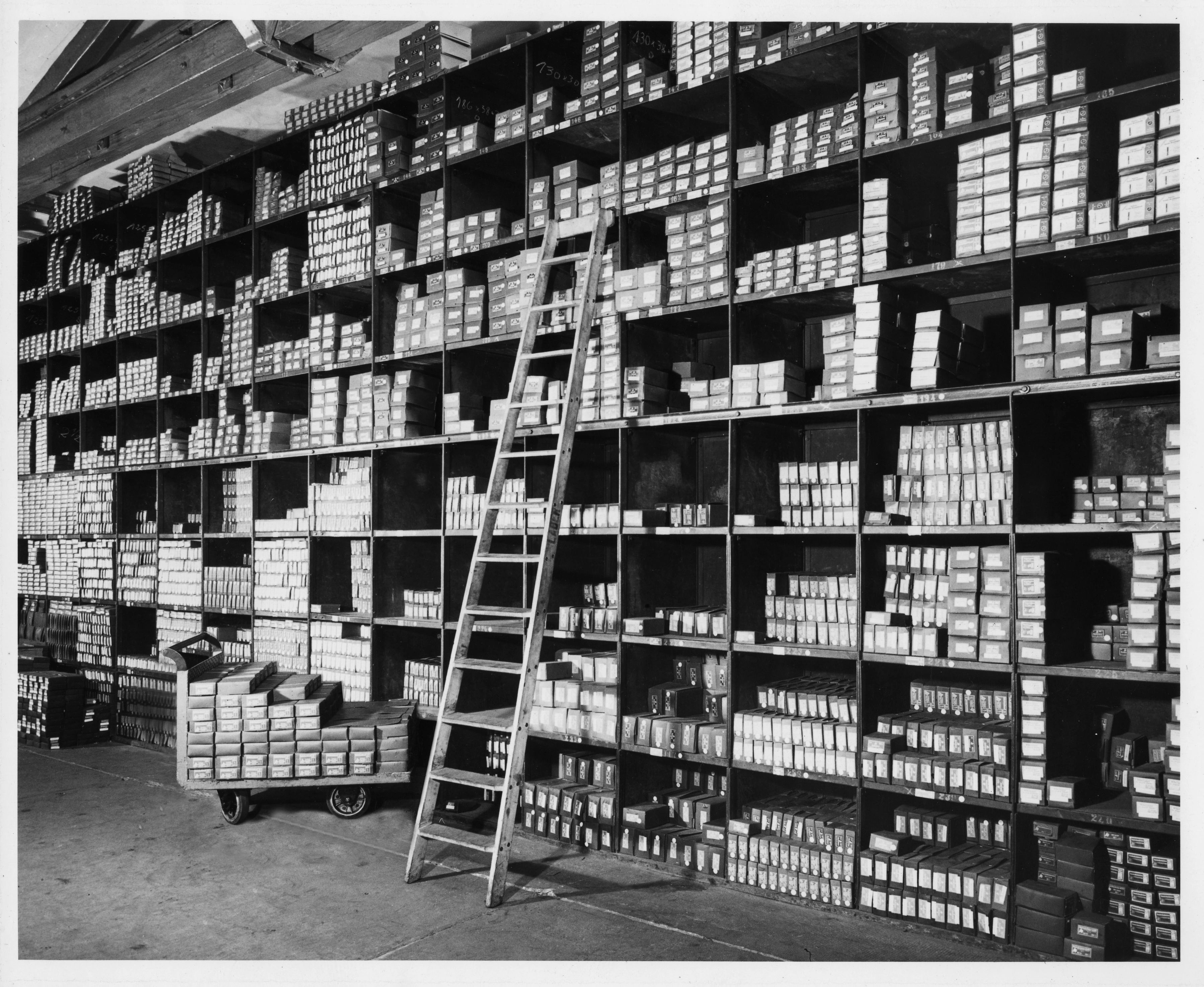

The new high-bay warehouse opens for the first time

1981

VARIANT VN system comes onto the market

1980

1979

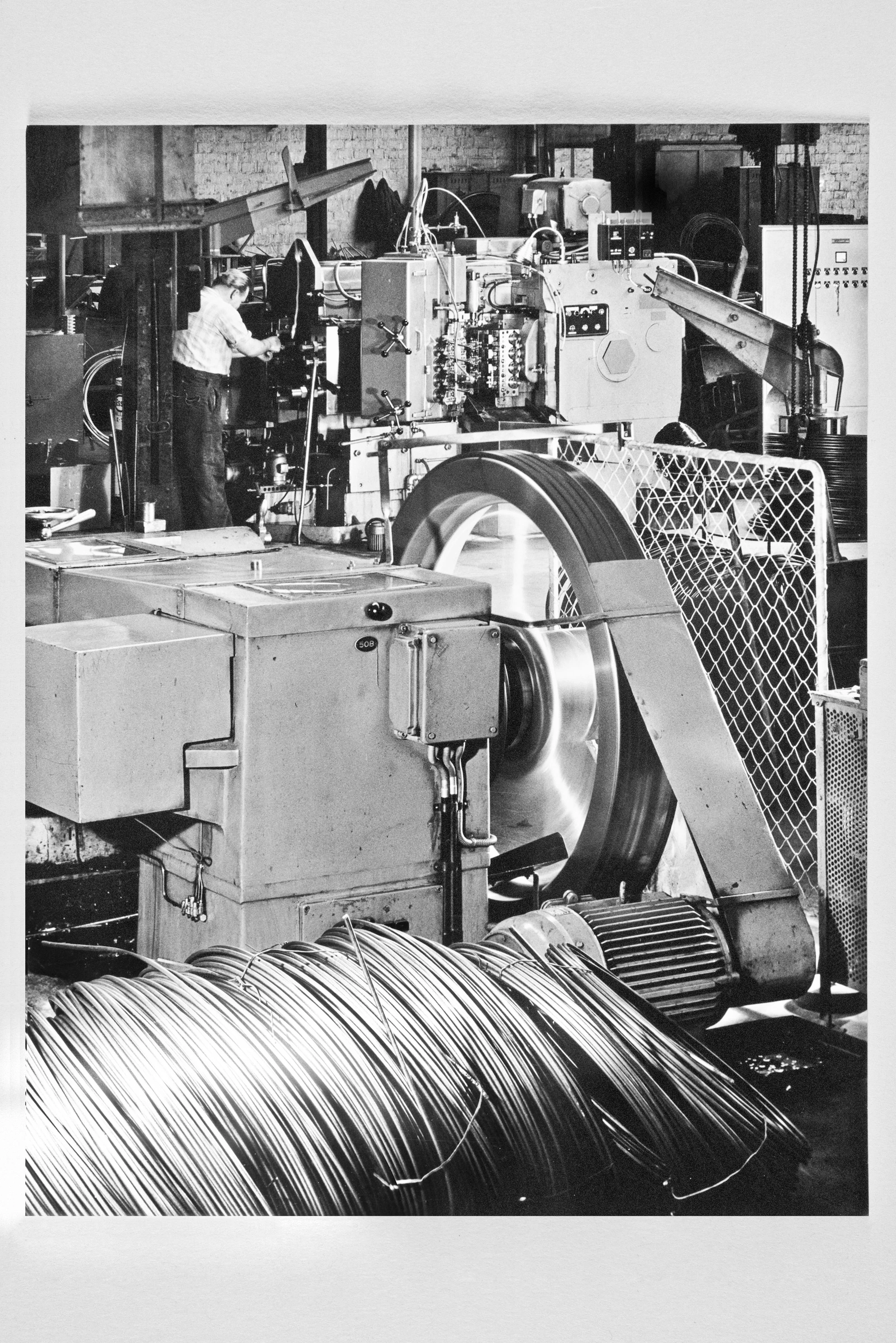

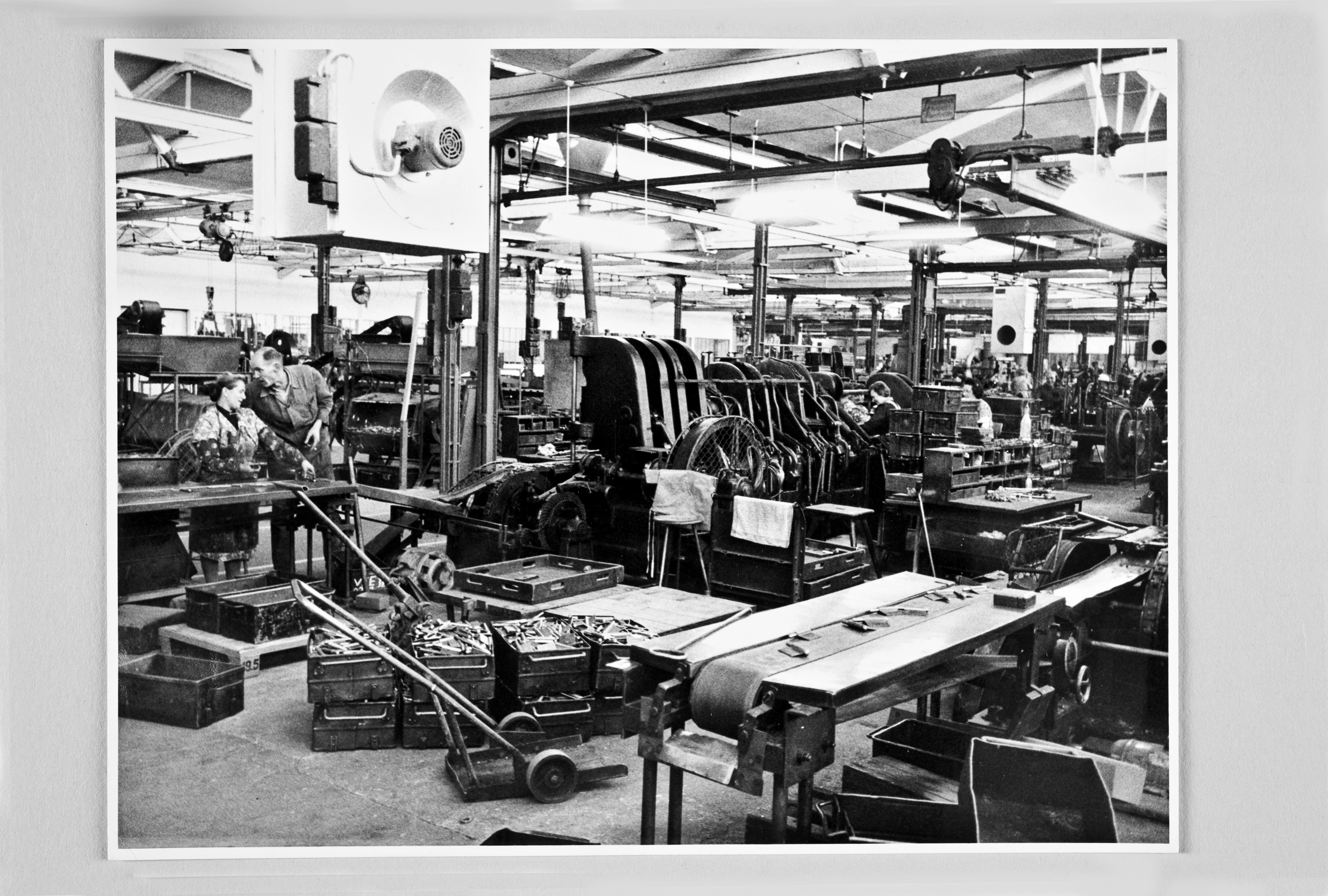

Modernising production

1967

Quality assurance

1963

VARIANT comes onto the market

1960

1958

The BAKA hinge system comes onto the market

1948

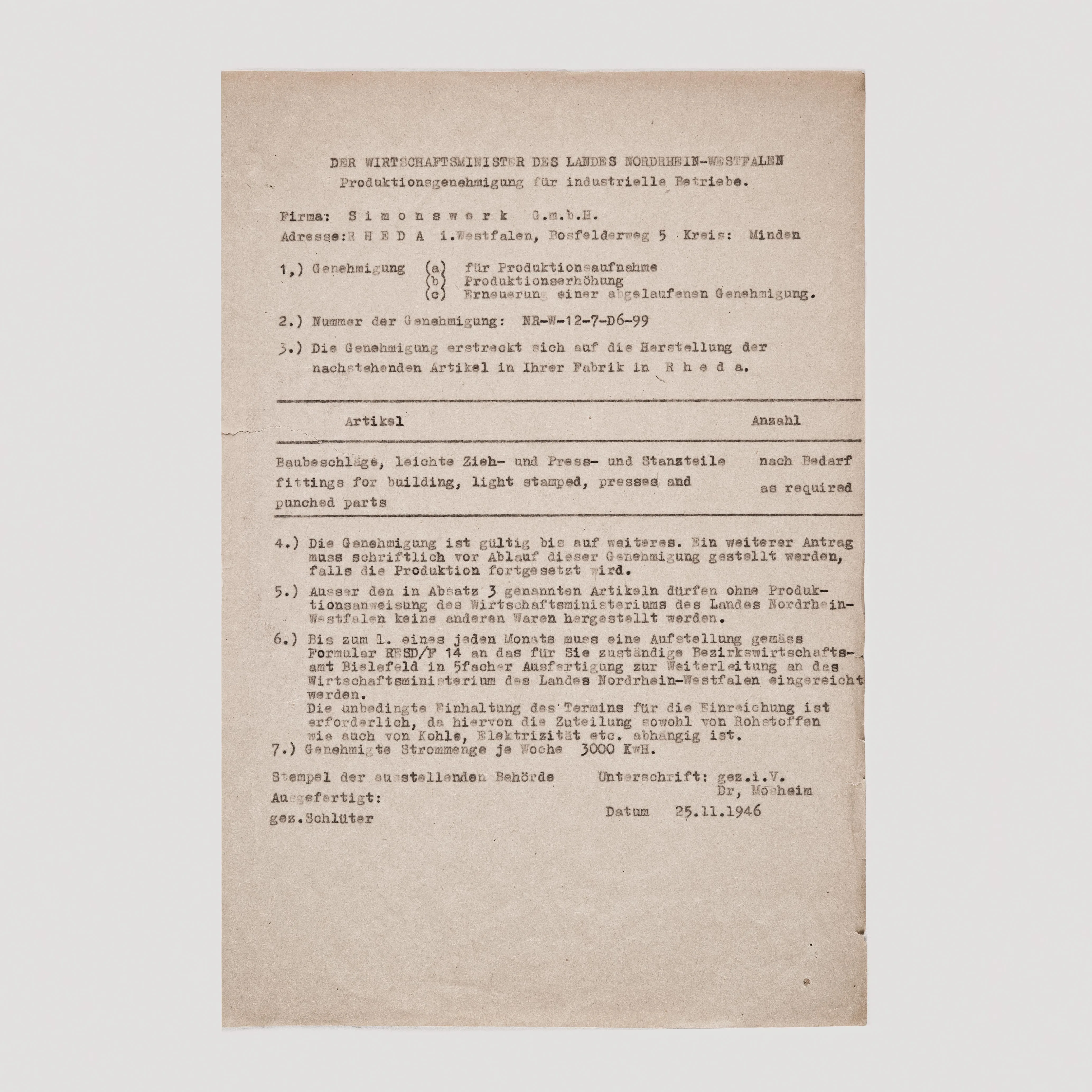

New currency, new business

1946

Reboot after the war

1945

Collapse and restart

1940

1930

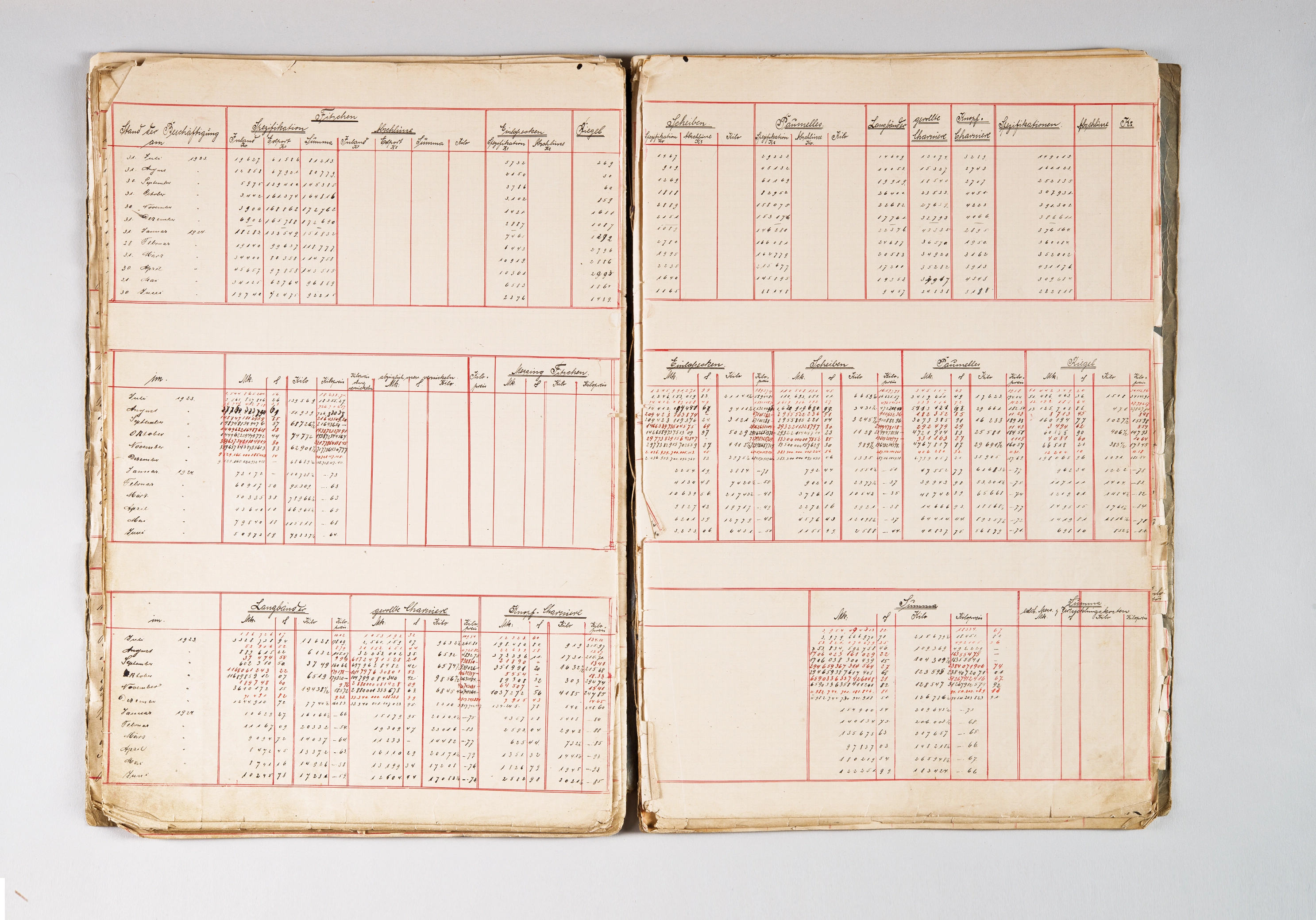

Introduction of S-lines

1921

SIMONSWERK in World War I

1910

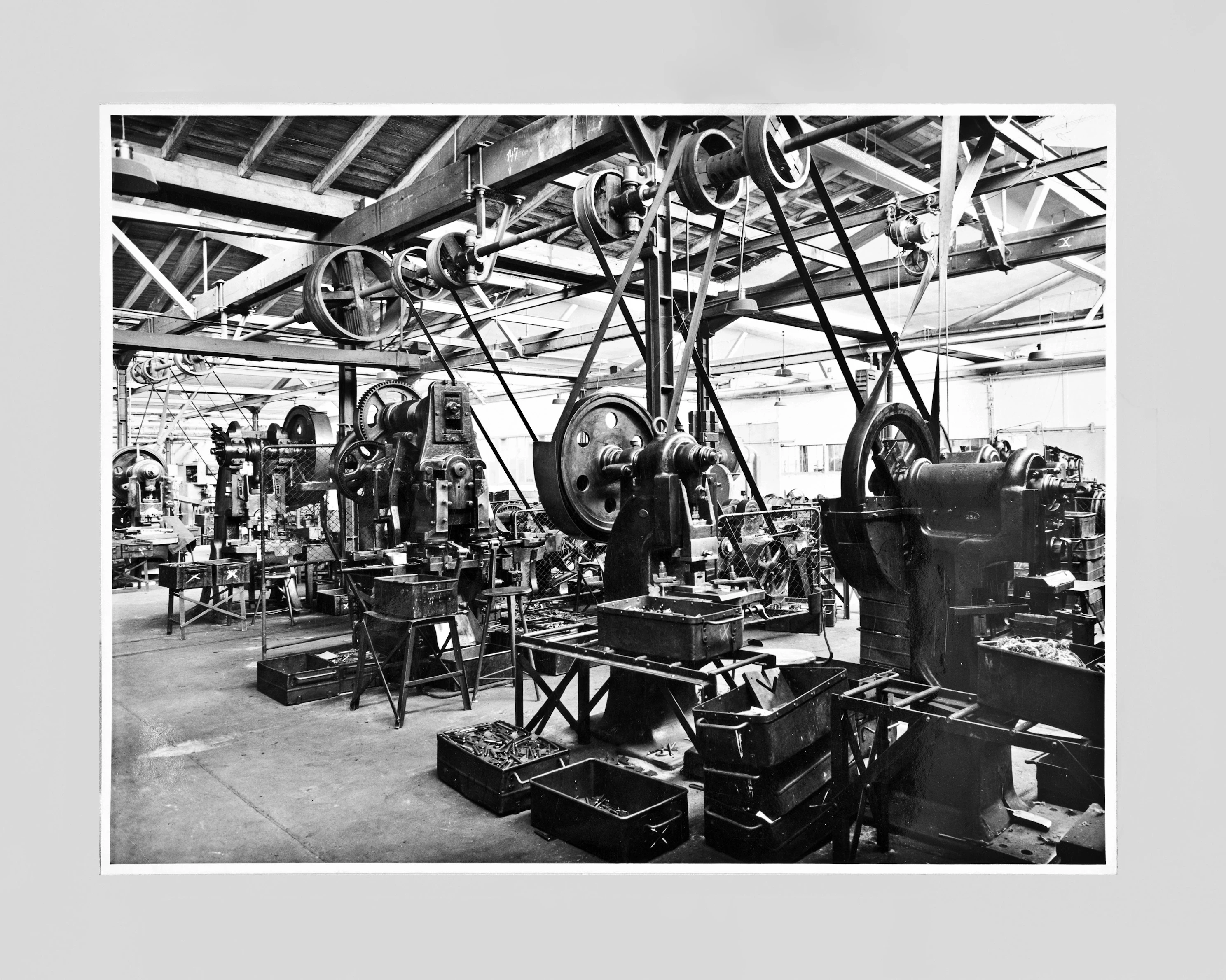

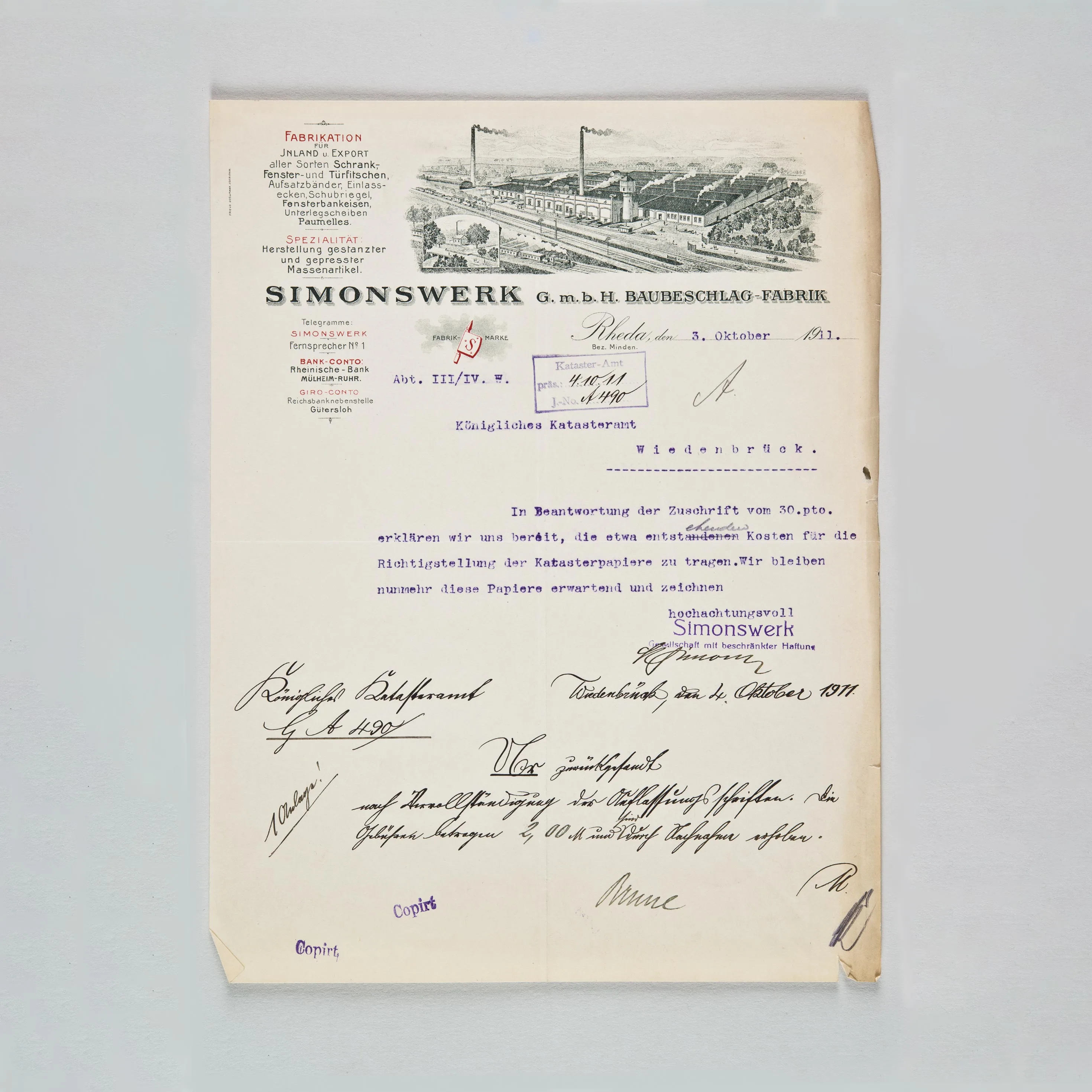

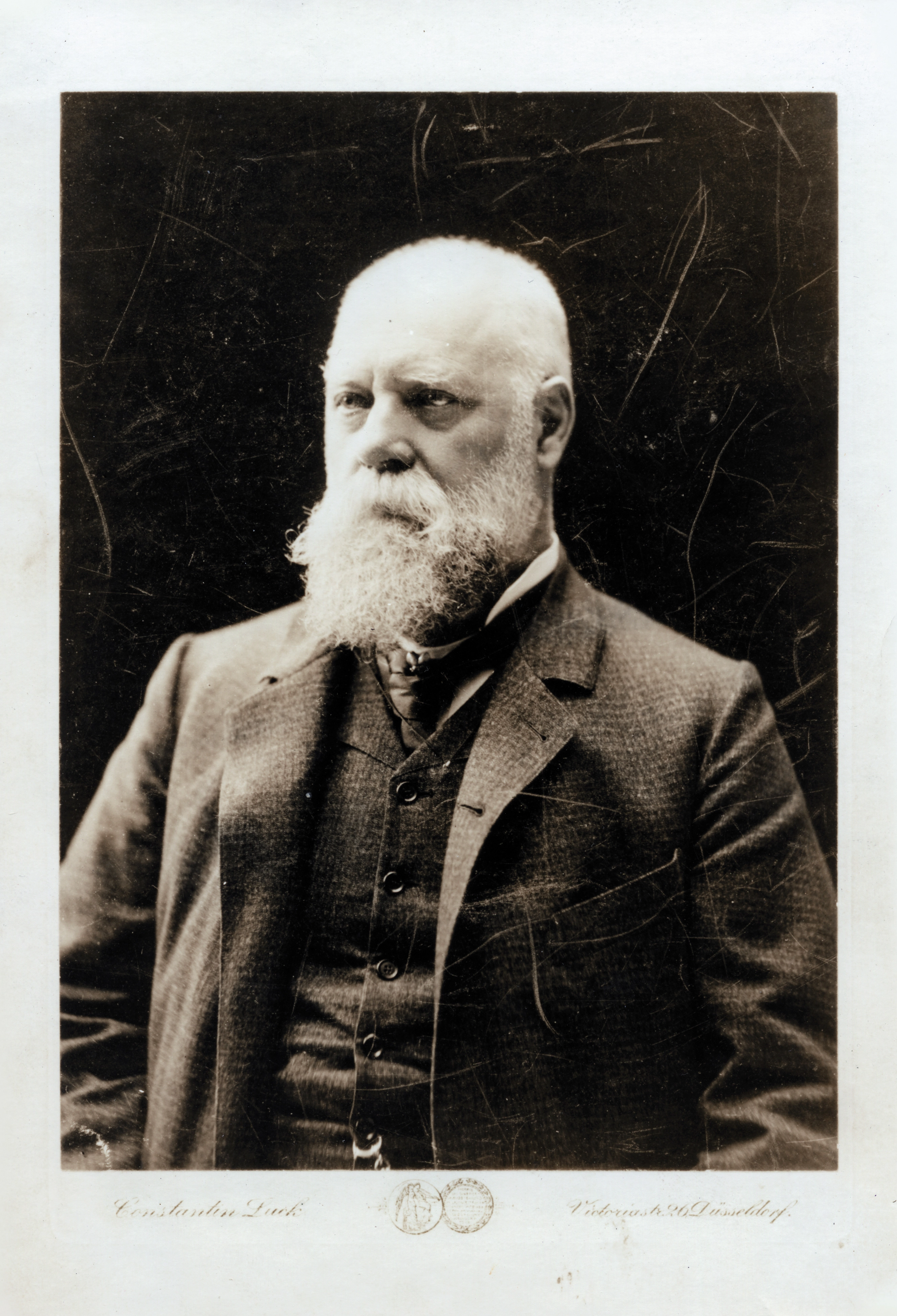

First modernisation measures

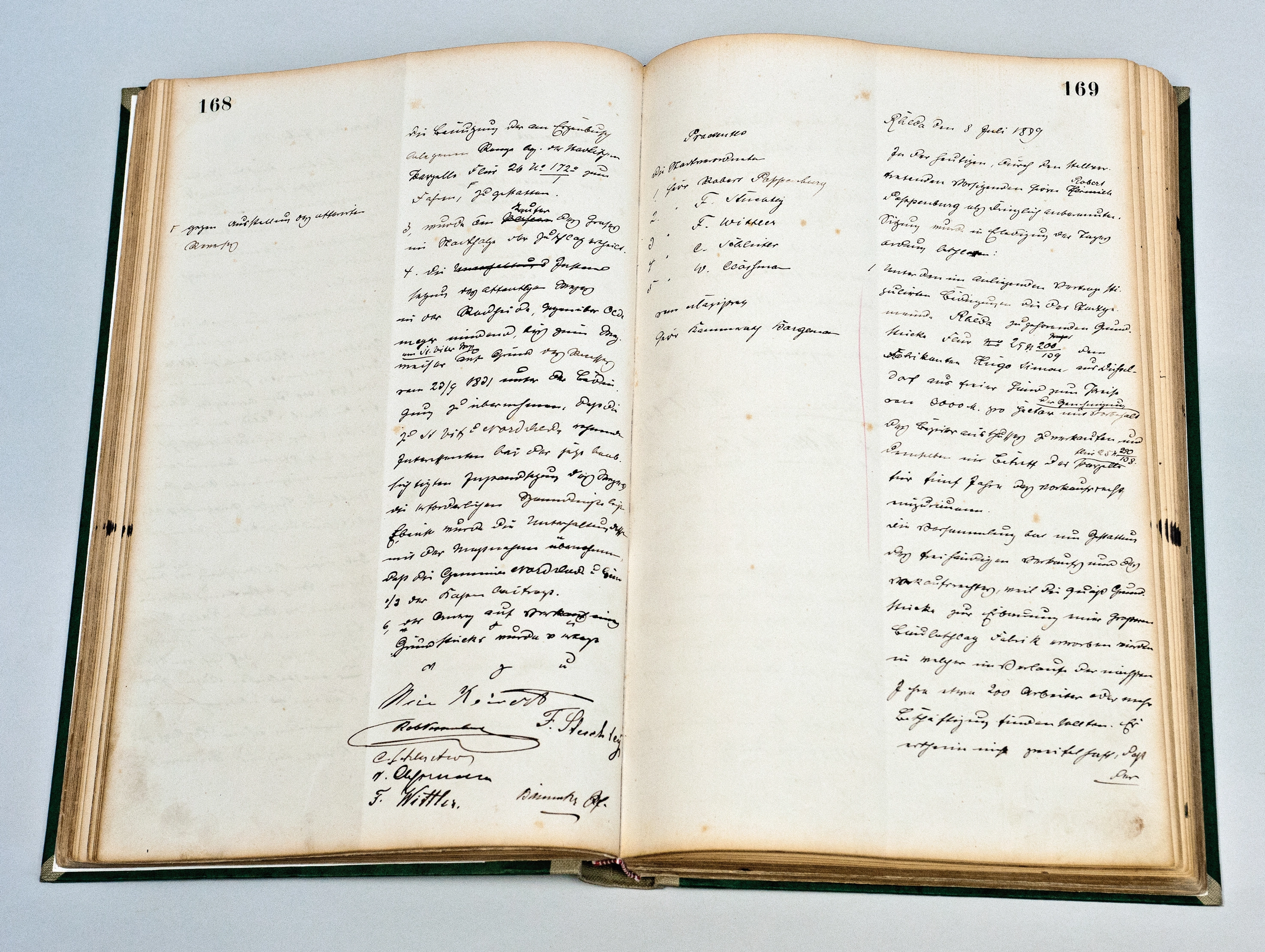

1909

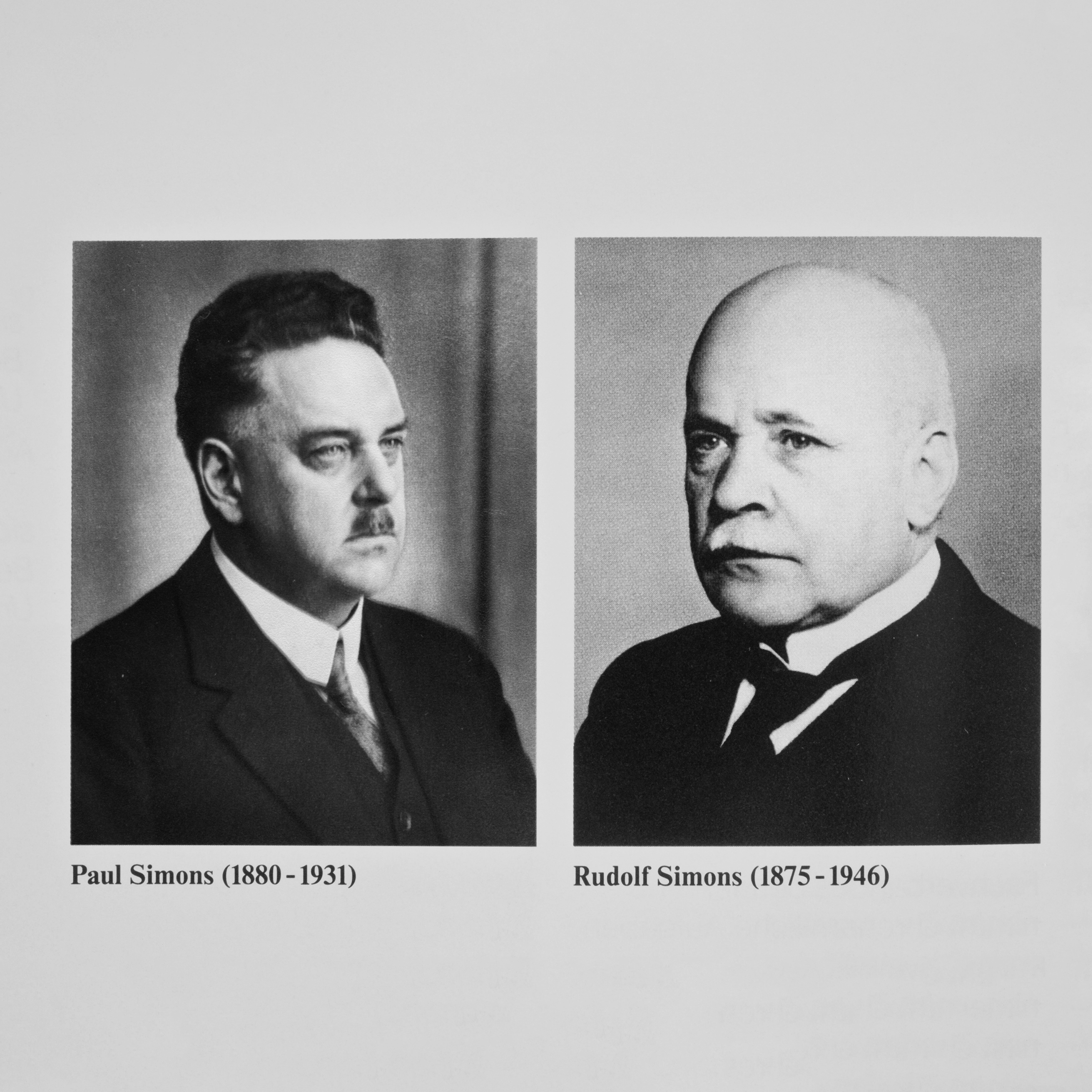

Takeover of the company management

1900

1897

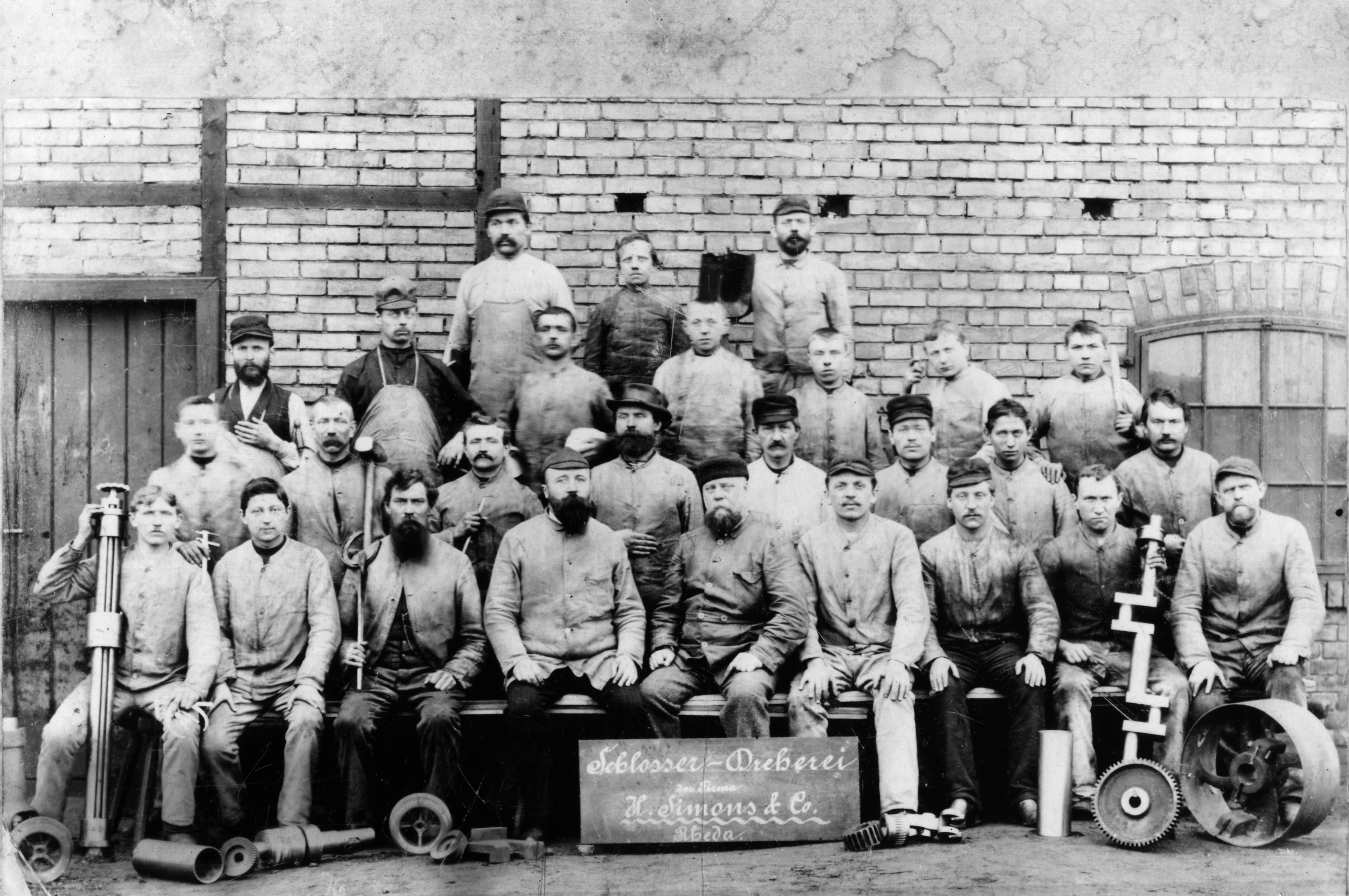

The company is already employing 250 people.

1889

Company founded by Hugo Simons

1880